Special solutions presented

Discover the diversity of our projects by means of selected examples

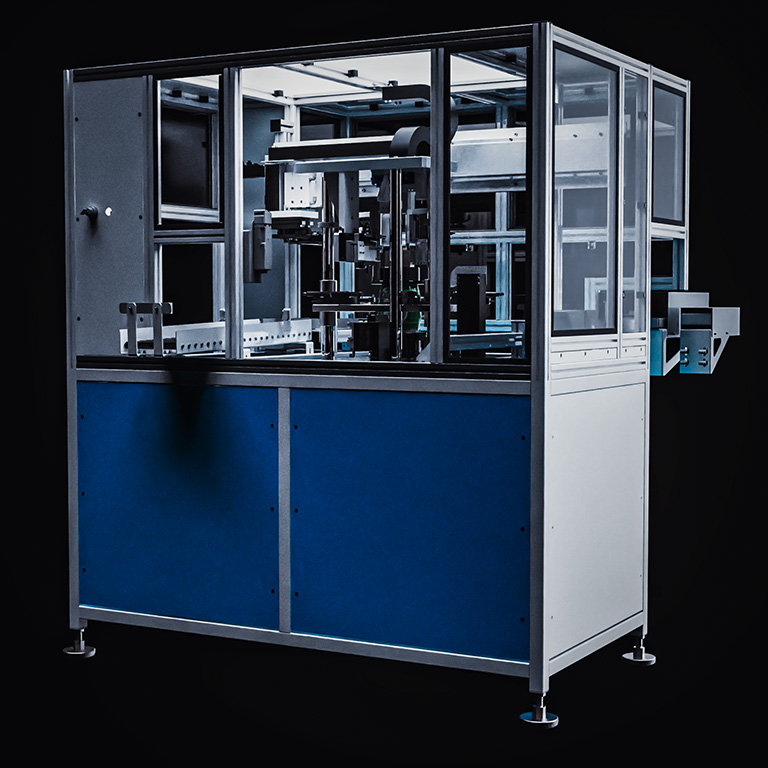

Fully automated measuring of beer kegs

Increasing requirements

The demand for ever more precise manufacturing and the associated documentation of results does not stop at one of Germany's most popular industries: beer brewing. In this case, the task was to randomly measure barrels rolled and formed from sheet metal for external characteristics. The system relied on the optimised interaction of optical and tactile measuring technology.

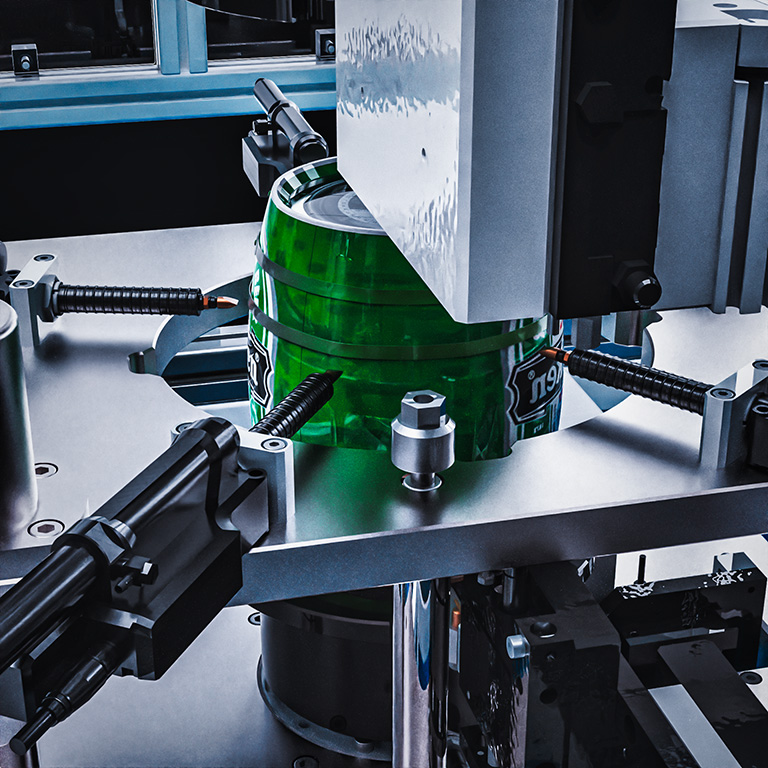

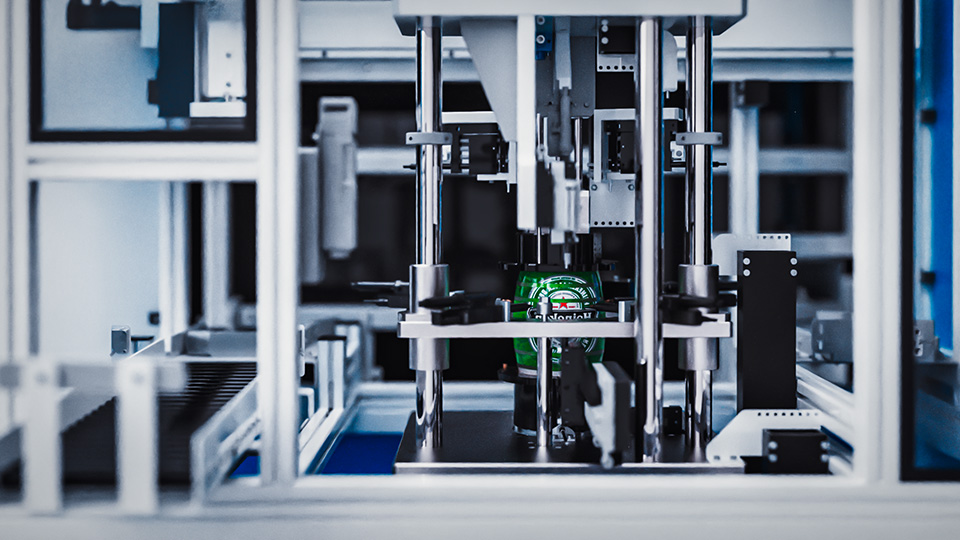

After successful infeed, the barrel is moved to the alignment position by means of a gantry with integrated vacuum suction cup. The exact alignment of the barrel is relevant due to the presence of mirror shadows and a weld seam, as a tactile measurement is carried out on the surface.

Measurement data acquisition & evaluation

A probing on these measuring points would result in an erroneous assessment of the barrel with regard to various characteristic values. The detection of these characteristics is carried out by an image processing algorithm developed by us and enables the detection of the interfering fields on a wide variety of colour spectra.

From the raw barrel measurement to the most diverse colour and contrast levels, mirror shadows can be detected and the barrel aligned accordingly. This is followed by a complete tactile measurement, in which the system's sophisticated control concept enables it to carry out even complex measurement processes. While the barrel is still being diverted back onto the conveyor belt, all data is already processed for quality management and can be forwarded to a higher-level ERP system.

Focal points of the project

- A total of 4 systems for the project (top and bottom measurement, barrel measurement and testing system for the tap)

- Barrel measurement with 14 features is carried out by tactile measurement strategy

- Diameter measurement with 5 probes laid out on 3 levels

- Optical alignment of the keg to avoid measuring on mirror shadows and weld seam

- Barrels in different colour spectra from matt to highly reflective

- Damage-free transport of the barrel (incl. transfer in and out)

- Vacuum suction cup for transport

- Designed for integration into existing production line

- Accuracy of ±10 µm

- Cycle time < 2 minutes per barrel

You have a task and are looking for the right solution?

Contact us. We look forward to a joint exchange.